OUR LOCATION:

Birmingham Road, Pathlow

Stratford-Upon-Avon, CV37 0EP

Safety Info - DB2 to MkIII Front Hub Failures Explained

- Manufacturer Part No: 55061

- Manufacturers Part No: 55062

Description

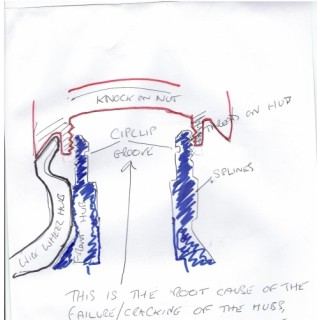

The ORIGINAL Aston Martin designed front hubs on a DB2 to DB MkIII have an inherent fault in their design, this causes the knock on nut with 4 or 5 threads to fall off the hub then the front wheel falls off, this is made more prevalent by overtightening the Knock-on nut and 60 to 70 years or so of metal fatigue - This failure can happen even on road cars.

There is no way of knowing if & when they will fail, crack testing can detect the start of a failure but no amount of crack testing of the hubs can find one if there is no detectable crack, but the instant the crack starts when the car is being driven a few seconds later the wheel will come off .

the text on the picture should read:

"This circlip groove is the root cause of the failure / cracking of the splined hubs, the action of tightening the knock-on nut stretches the splined hub as the wire wheel hub centre is quite strong & by its shape fairly elastic, the splined hub is stretched beyond its elastic limit by the nut & wheel causing the crack to emanate from the circlip groove, exacerbated by sharp corners built in to the hub by AML"

This failure emanates from the circlip groove machined into the inside of the hub, the circlip is used to locate the outer ring of the outer bearing, the solution was to remove the circlip groove from the hub & make the wall of the hub thicker by using an outer (small) double row bearing with a smaller outer diameter., same width & same inner diameter, with the inner bearing (large) remaining the same as the original part.

This solution was 1st manufactured by Andy Hodge of Andron Engineering in the early 80s for use on Jon Gross's & Andys Aston DB MkIIIs, he redesigned the front hub & started making them for others, there are now several people producing them, we sell ours with taper roller bearings & a very special stub axle nut, having seen the hub nut fail on another type of car.

This was the 1st Andron hub & is still in use today, when we started using the race DB2s in 2005 in longer events (6 hours or more) we saw failures of the front wheel bearings supplied with these hubs, so we started using taper roller bearing conversions & special grease in our own race hubs, (largely made to the original Andron design but deleting the 2BA grub screw (which was found to be not needed) for locating the inside hub seal carrier which caused grease to leak from the screw thread into the brake drum / onto the brake disc & gave associated failures with the front brakes, the special grease significantly reduced the hub temperatures due to reduced friction.

Then we started seeing the bearing failures on well driven or higher mileage road cars so we fitted the taper roller bearing kits without the special grease to road cars so that is where we are now with the hubs except for a few hub locating failures which we have redesigned the hub nut with an integral washer & better material.

We have re-designed the bubs again in 2021 to improve them some more, see 55061 & 55062 front hubs

There are now 3 types of hub, these fit Drum & Disc brakes cars, as listed below:

Full Race with taper roller bearing & special grease, Solid steel hub spacer, special adjusting procedure, special nut

Rally with taper roller bearing & special grease, no spacer so adjust as per normal taper roller bearings & leave a small amount of play, special nut

STD road hub for fast road aswell, taper roller bearing & standard hub grease, no spacer so adjust as per normal taper roller bearings & leave a small amount of play, special nut

The only other thing to say is most front hubs are worn out now with sharp splines & wear marks on the locking taper just before the drum / disc locating boss.